|

What

follows now is the sequence for first creating the "burr"

or "wire edge" on the tool and then in succeeding steps,

removing it by abrasion and and fatiguing the metal by alternately

rubbing the bevel, then the back, onto the stone. The steps (shown

on the previous page) for holding and moving the tool on the stone

are always the same regardless of where in the honing procedure

we are.

Hint:

at first, try stopping at the end of each stoke to check the solidity

of the down holding pressure on the bevel. The bevel should "click"

against the stone. As your hold-down technique becomes consistently

good progress to continuous back and forth strokes.

|

|

|

| Feeling

for a burr. Always feel by moving your finger

from the back of the chisel off the edge, not onto the edge. |

|

| The

burr or wire edge on the back |

|

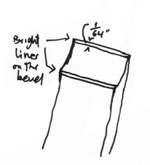

1.

If tool is fresh from the grinding wheel, rub until a bright line

appears on the bevel all along the cutting edge and the heel (=

20-30 strokes). (Note: Do not rub back of tool yet.) The

bright lines are flats abraded by the stone; they needn't be wide.

A scant 1/64" is enough.

2.

If tool already has the bright lines (i.e., was previously honed

on an oilstone) then rub till a slight roughness (a "burr"

or "wire edge") can be felt on the blade's back, just

behind the cutting edge. This burr should be palpable all along

the cutting edge. Keep checking your progress. When examined under

a bright light no light should reflect on

the edge itself (on the edge viewed from the end, not the flats

on the bevel). Any reflected light indicates dullness. Sharp edges

reflect no light!

|