|

|

Table of contents |

A Guide to Honing and Sharpening

Introduction

|

One of the most important skills a woodworker can acquire is the ability to sharpen tools easily and well. Working with hand tools can be a frustrating experience unless you have sharp tools. The goal of this lesson is, with a mimimum of equipment, is for you to be able to produce razor sharp cutting edges on any tool blade consistently. This lesson focuses on honing. It was written by Maurice Fraser and is based on material and techniques taught in his classes at the Craft Students League in New York City. Maurice has been teaching woodworking for over 25 years and was a frequent contributor to Fine Woodworking magazine in additon to many other publications. Editing and additional material on the history of sharpening was provided by Bob Mathison, Curator of the Museum. There are three areas of expertise in sharpening:

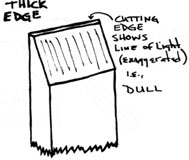

What are sharp tools We could describe a sharp tool as one you can shave with. This doesn't mean that unless a tool is sharp enough to shave with it's useless, or that you should be shaving with your tools, but it does give a frame of reference that is easy to understand. However, for the purposes of teaching sharpening we can come up with a less subjective description. Click on the picture to enlarge

Why Sharpening Guides Make it Harder The most important thing you can come away with from this lesson is the technique for holding and moving a tool on a stone. Most sharpening lessons deal with the technology and sharpening sequence and leave this part out. But free holding a tool consistently and easily is the key to sharpening easily and well. It's not that difficult at all. There are a tremendous number of products on the market designed to hold a blade at a consistent angle to a honing stone. However, almost all of them share two important flaws: The jigs allow you to repeat a motion but always in the same part of the stone. For waterstones this means the stones will wear in certain spots faster and require more maintenance. The second problem with honing guides is more subtle: The first time you sharpen you establish some sort of bevel. The second time you sharpen you need to maintain the same exact bevel; The important word here is "exact"; If it's not exact, you tend to create a secondary and then tertiary bevel at each attempt at sharpening. This makes for much more work. Even if you can get really, really close to getting the same bevel, setting a tool in a jig exactly is tedious and very hard to get perfect. And it takes time. You'll find it a great pleasure to be able to just take a tool and immediately put it onto a stone without having to worry about setting up a jig. Jigs and guides do have a place. We do use jigs for holding tools when we grind them and for really rough honing where a grinder is not available and we have to remove a lot of metal using a coarse stone. And we sell all sorts of jigs in our Museum Store. Therefore please realize we are not trying to present a "religious" argument but simply trying to show you how we make it easier. An argument made against hand tools is that it's hard to make them work. A hundred years ago and more, people made hand tools work. They had no choice: they didn't have power tools. Woodworkers were able to be productive by having the right tool and developing the skill to maintain and use it properly. If you can duplicate that skill, you can be just as productive. |

||||||||||